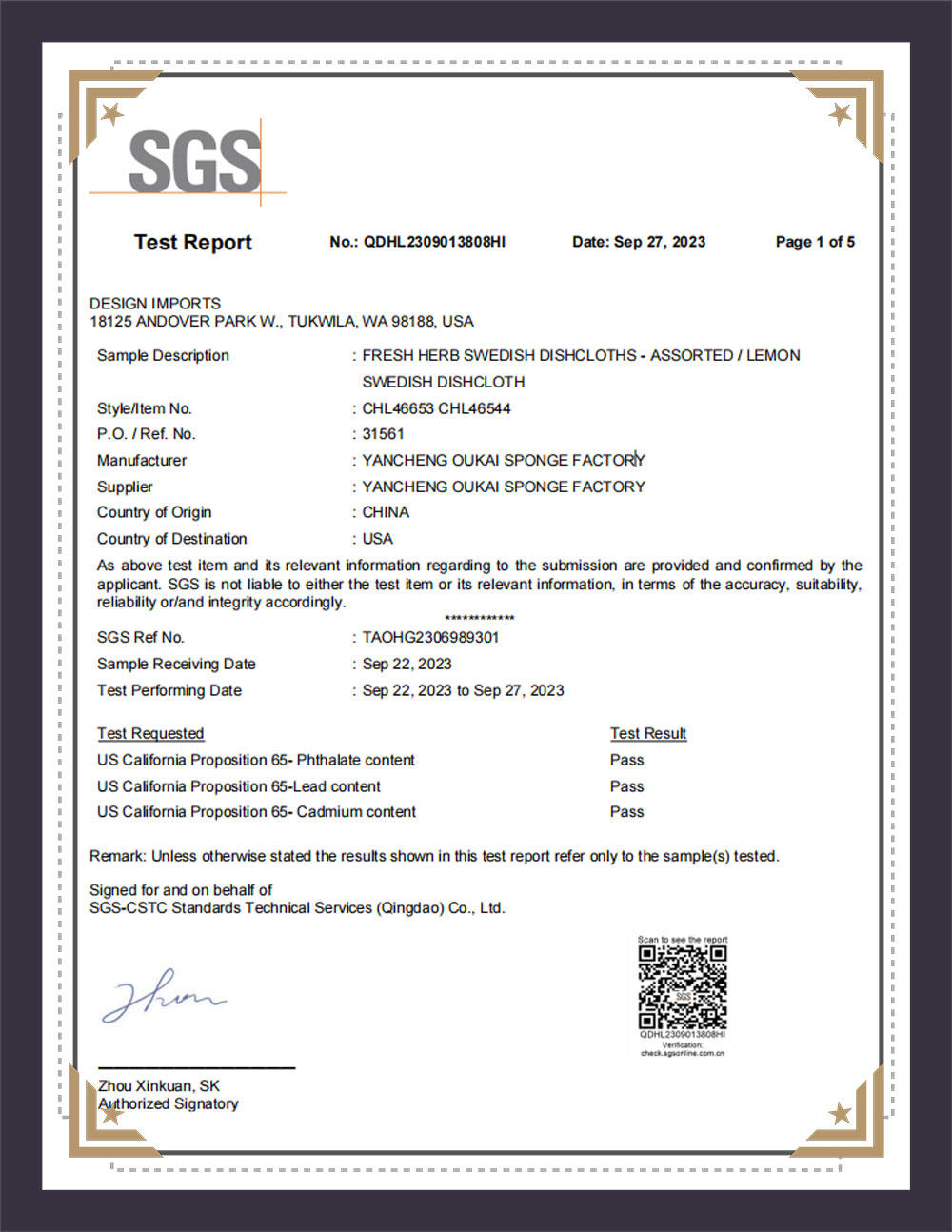

Cellulosesvampe er sikre til opvask. Cellulose svamp end den generelle svamp rengørings...

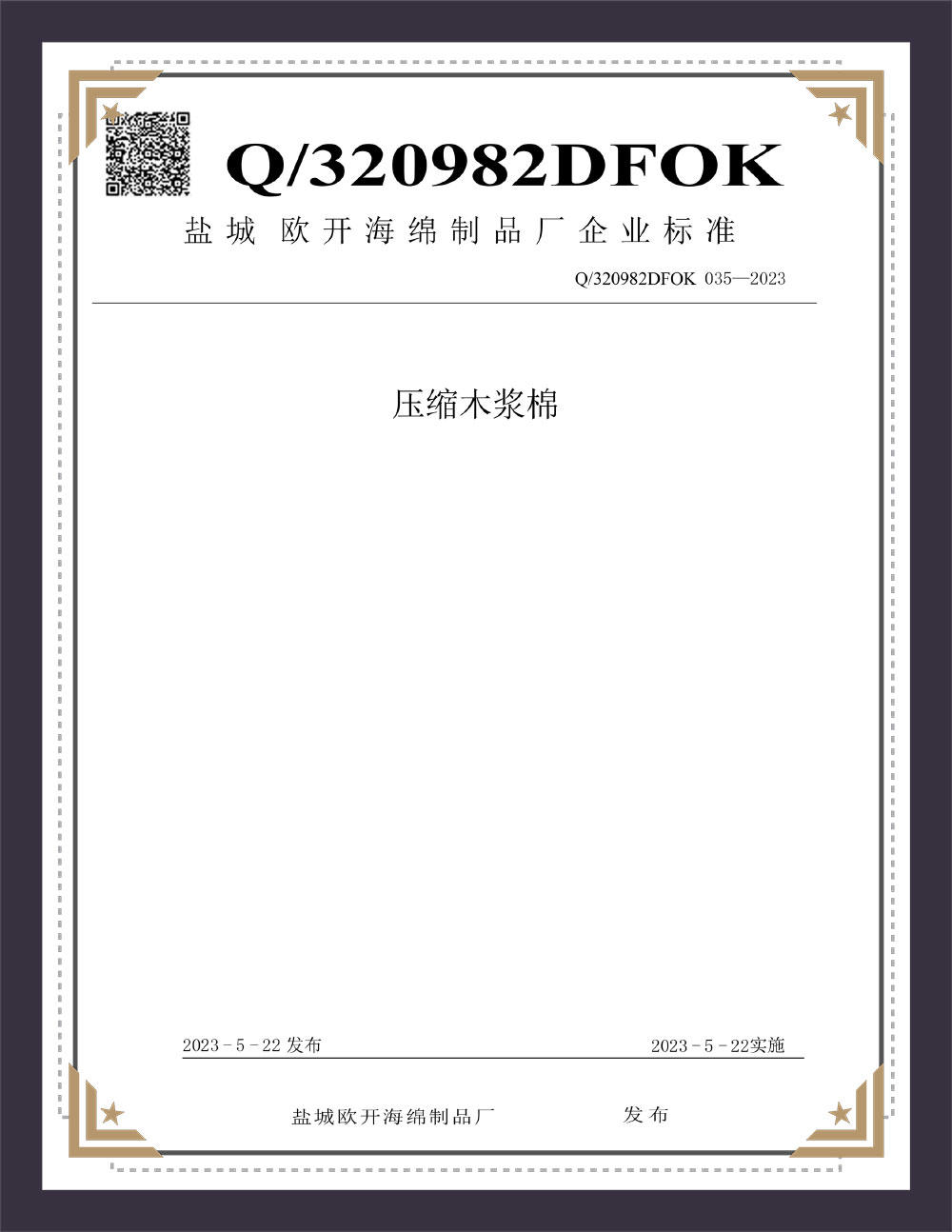

Komprimeret cellulosesvamp

Den komprimerede cellulosesvamp. Dette er fremstillet af træmasse bomuld efter høj temperatur varmpresning. Den komprimerede cellulosesvamp bibeholdt ikke kun alle fordelene ved træmasse-bomuldssvamp, men efter presning reducerede vi svampens volumen for at gøre forsendelsesgebyret lavt, vi kan også udskrive logoer eller andre designs på overfladen. Det gør rengøring sjovere.

-

Industri nyheder

Hvordan adskiller Natural Bath Sponge sig fra kunstige svampe?

1. Materiale: Natural Bath Sponge er lavet af svampe fra naturlige svampe, såsom svampe. Disse svampe vokser normalt i...

-

Industri nyheder

Hvad er de mest almindelige anvendelser for køkkenrengøringsskure?

1.Vask gryder og pander: I køkkenet har gryder og pander ofte madrester og fedt, som er svære at rengøre, og det er her...

-

Industri nyheder

Hvordan påvirker teksturen af komprimeret cellulosesvamp rengøringsydelsen?

1. Absorptionskapacitet: Teksturen af komprimeret cellulosesvamp påvirker i høj grad dens evne til at absorbere væske...

-

Industri nyheder

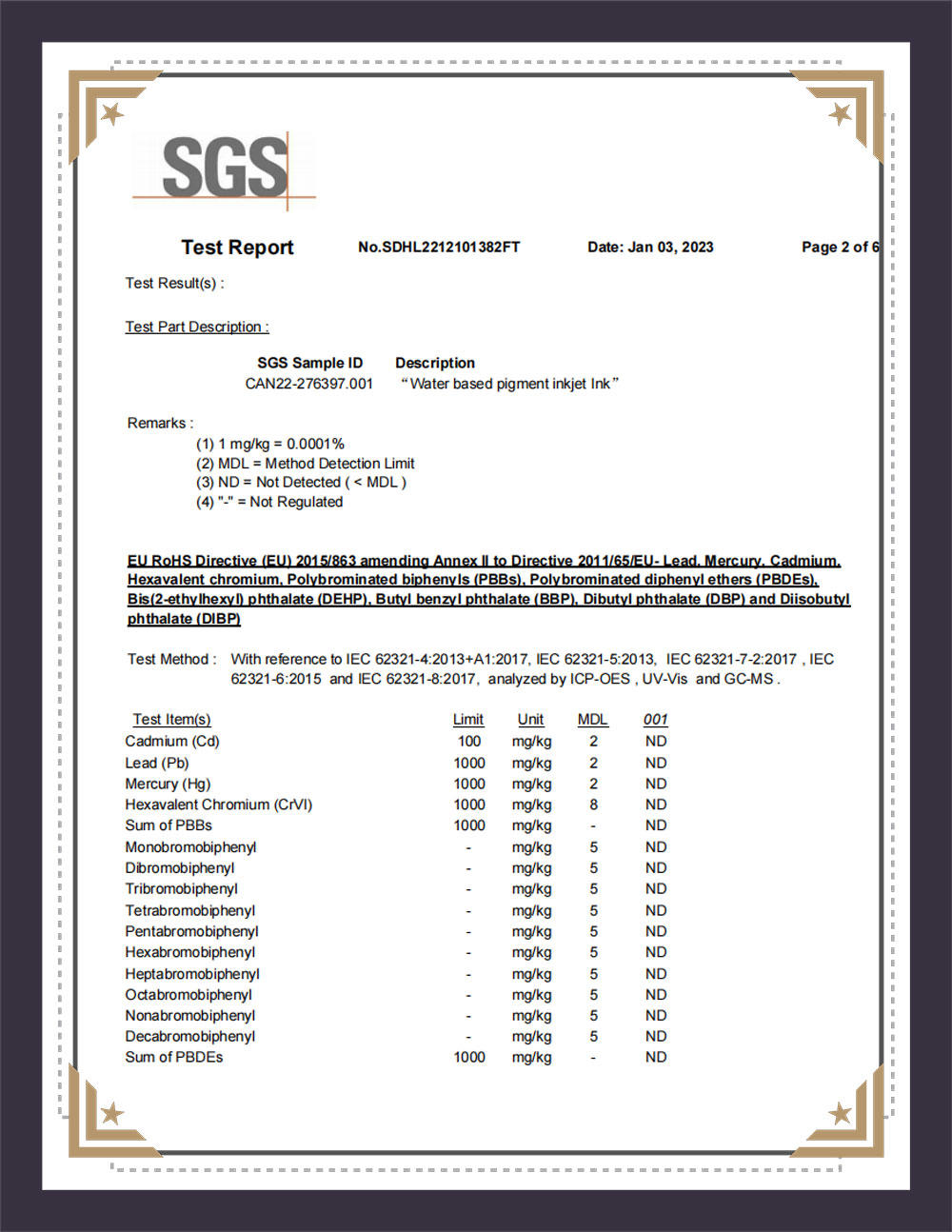

Er der nogen kemikalier, der skal undgås i køkkensvampe?

1.Triclosan: Triclosan er et syntetisk kemikalie, der almindeligvis tilsættes til antibakterielle svampe og andre husho...

简体中文

简体中文